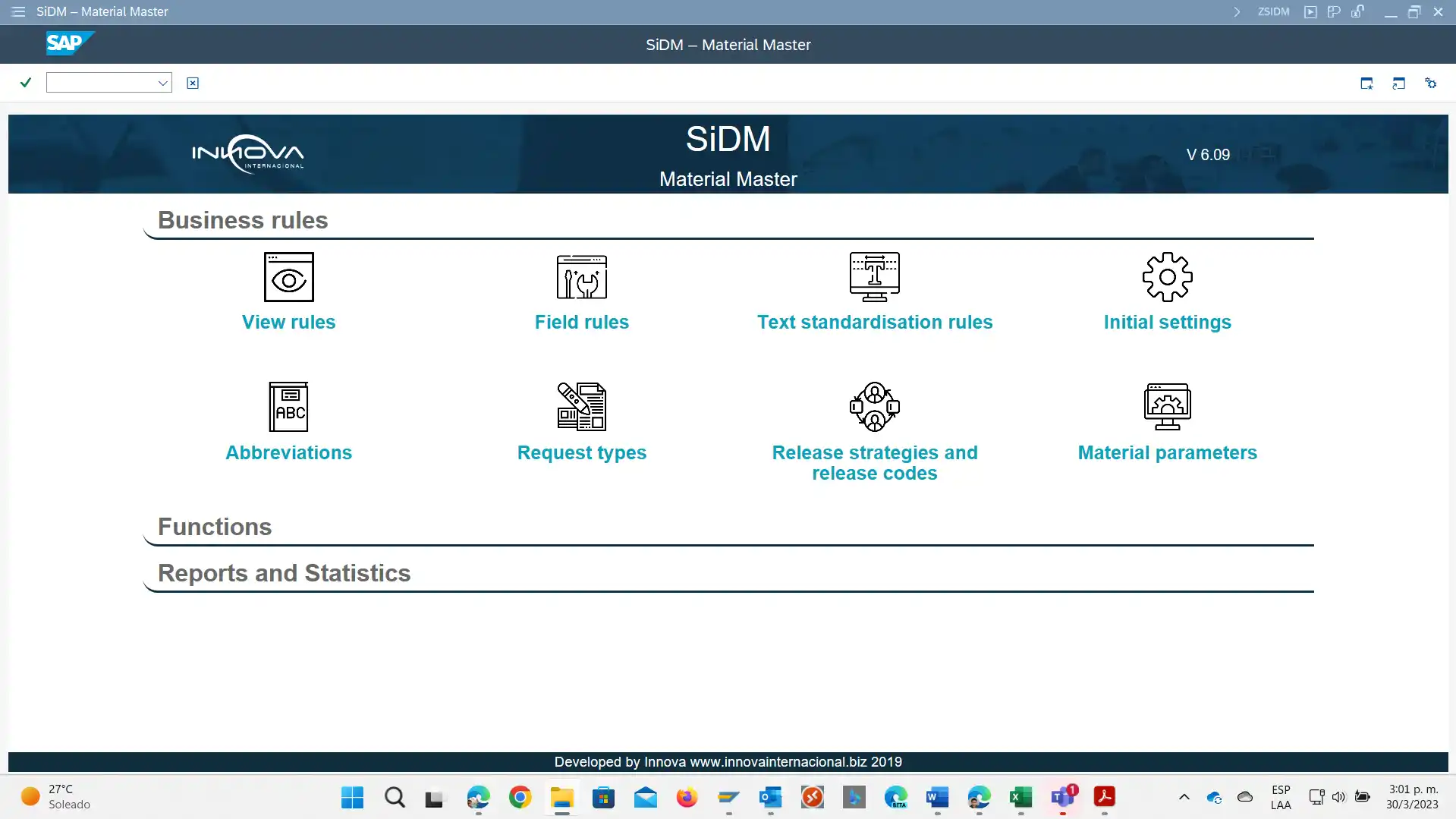

SiDM Materials

Better data, better processes.

Data quality and governance for all materials or items (Retail) in SAP, through business rules and release strategies, in a single transaction with great user experience.

Main functions

Business rules

- No technical or programming knowledge is required. You can define rules for organizational units where a material should be created, correct values, and how to automatically build the texts of the material.

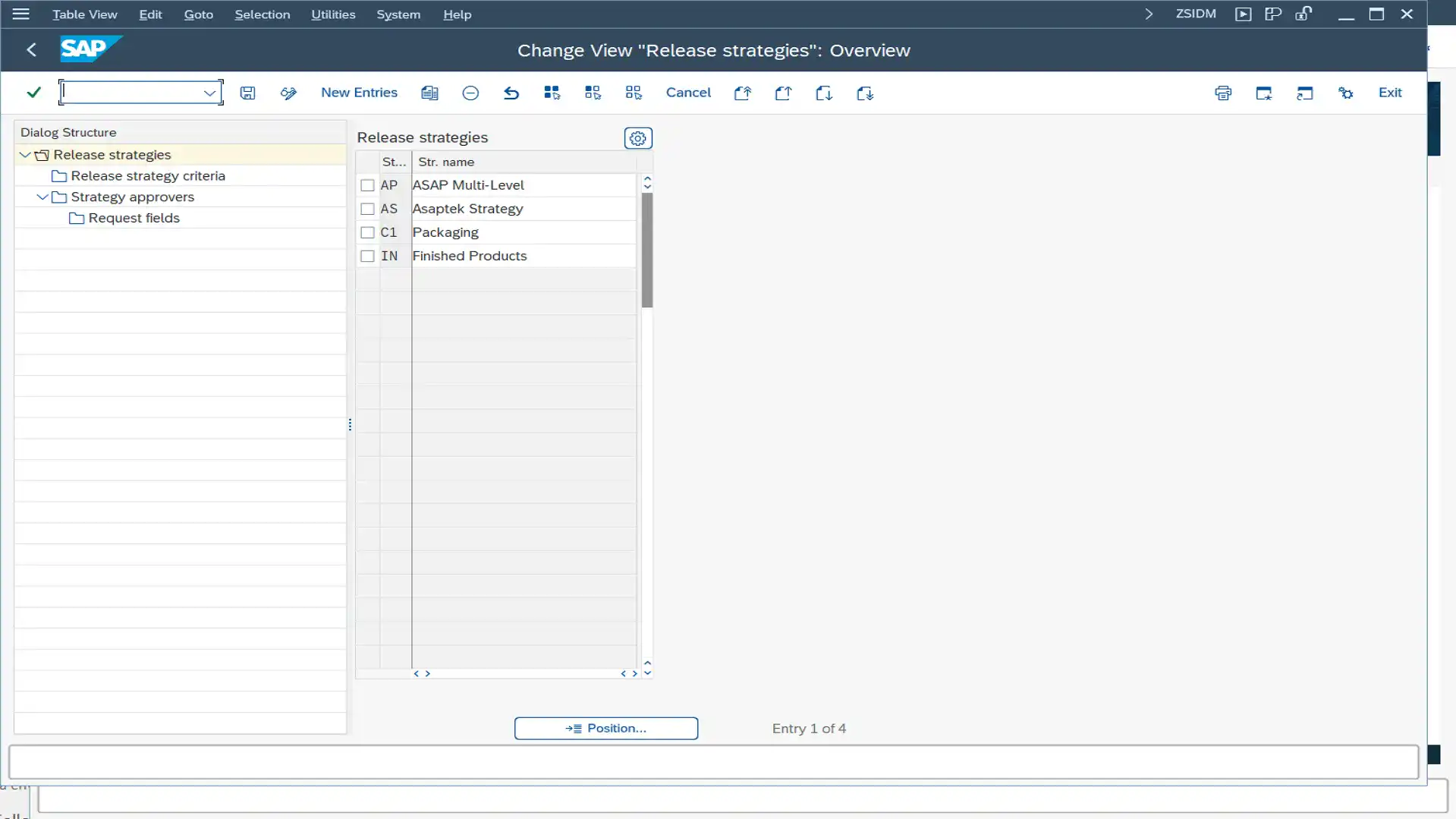

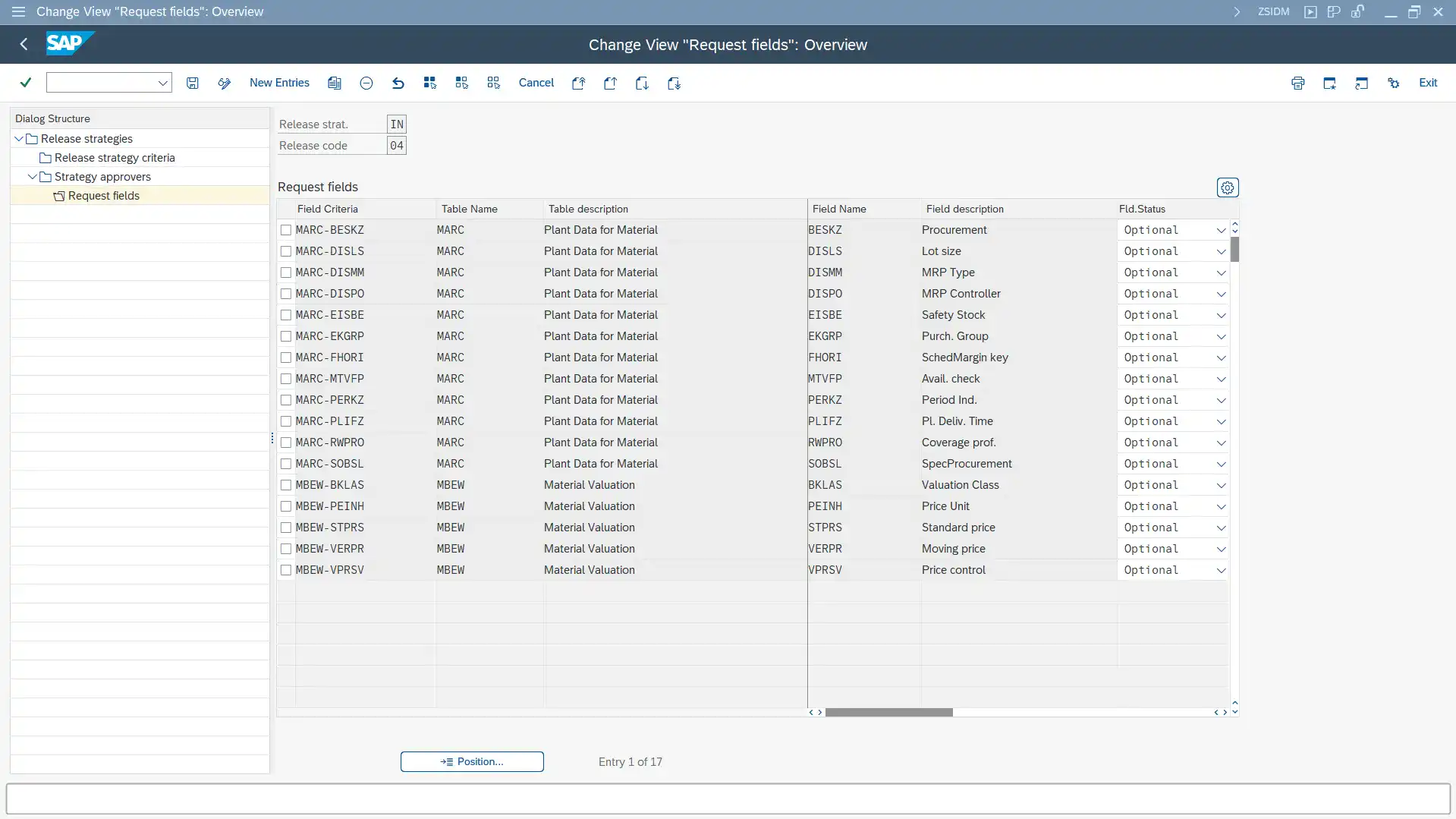

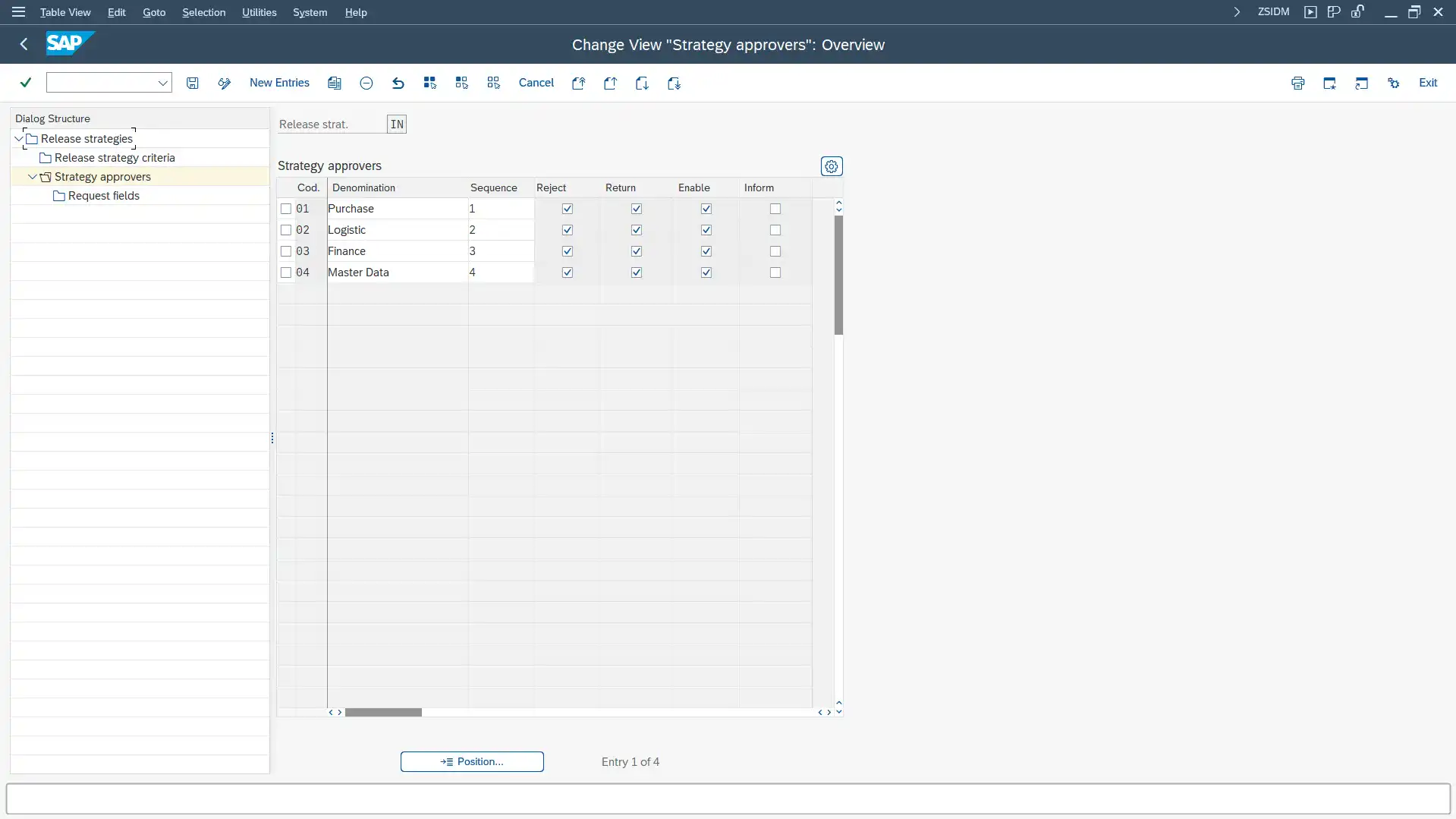

- It is also possible to define the creation/approval flows, the participants, and their responsibilities in the process of creating a material.

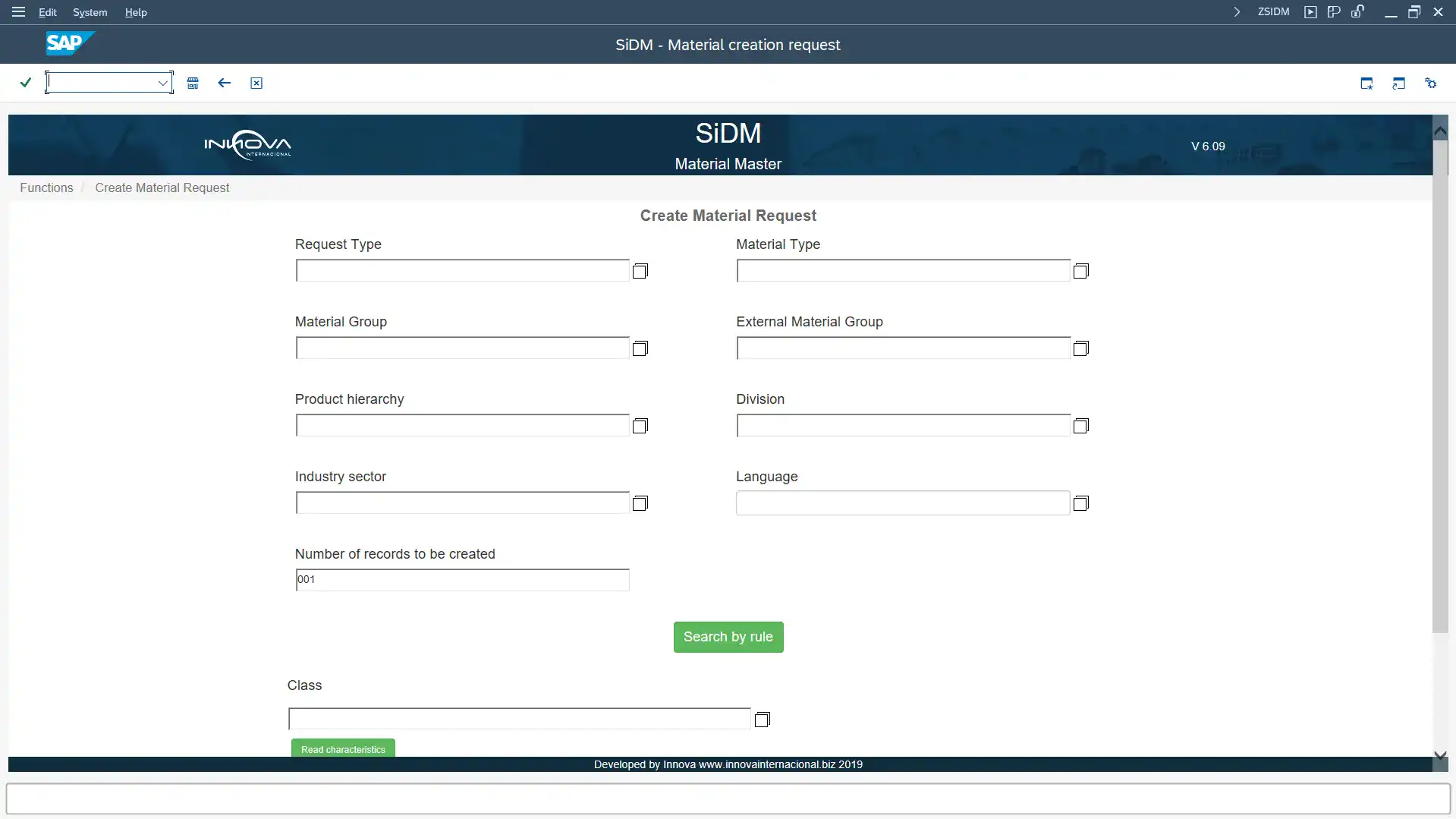

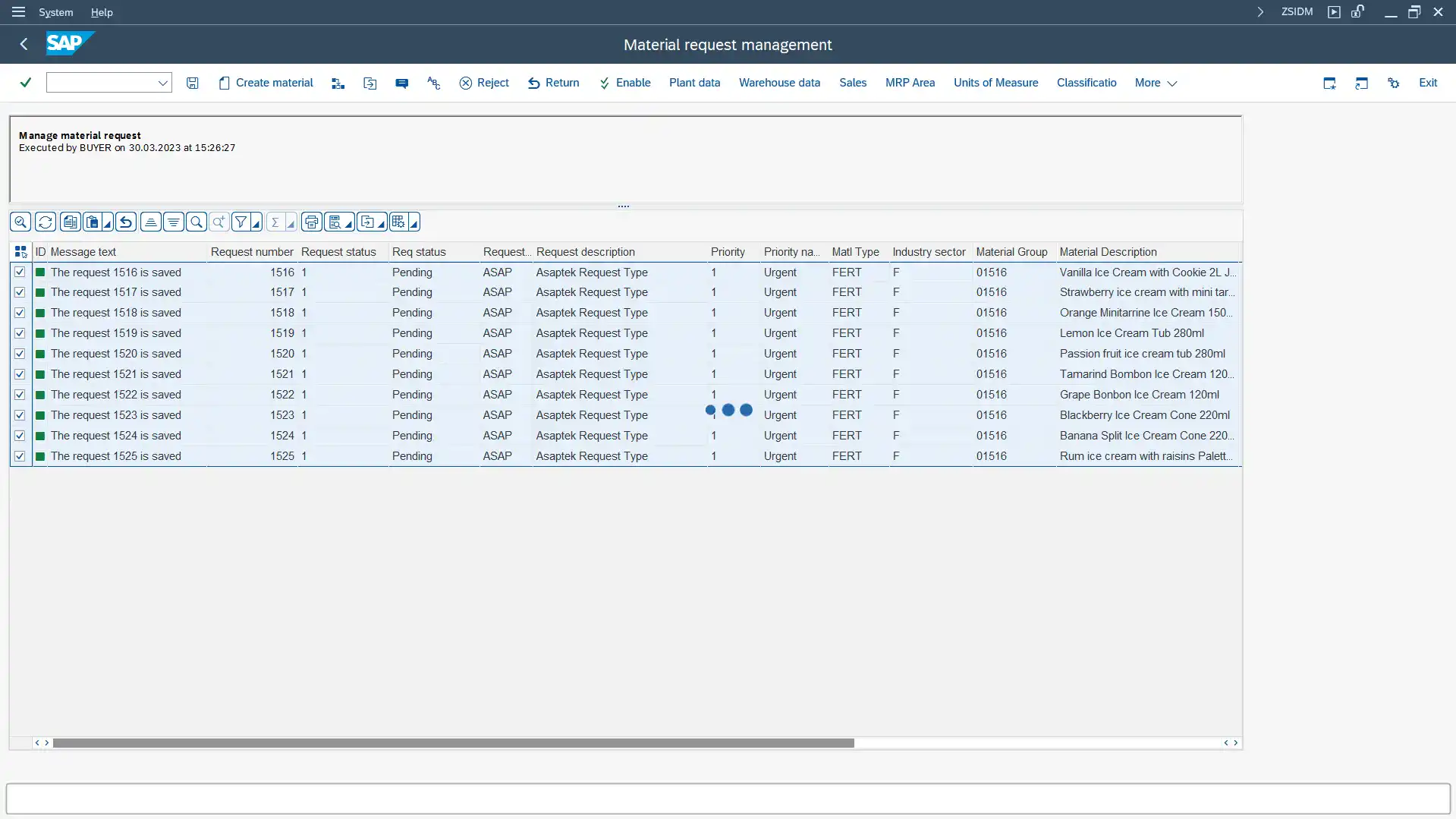

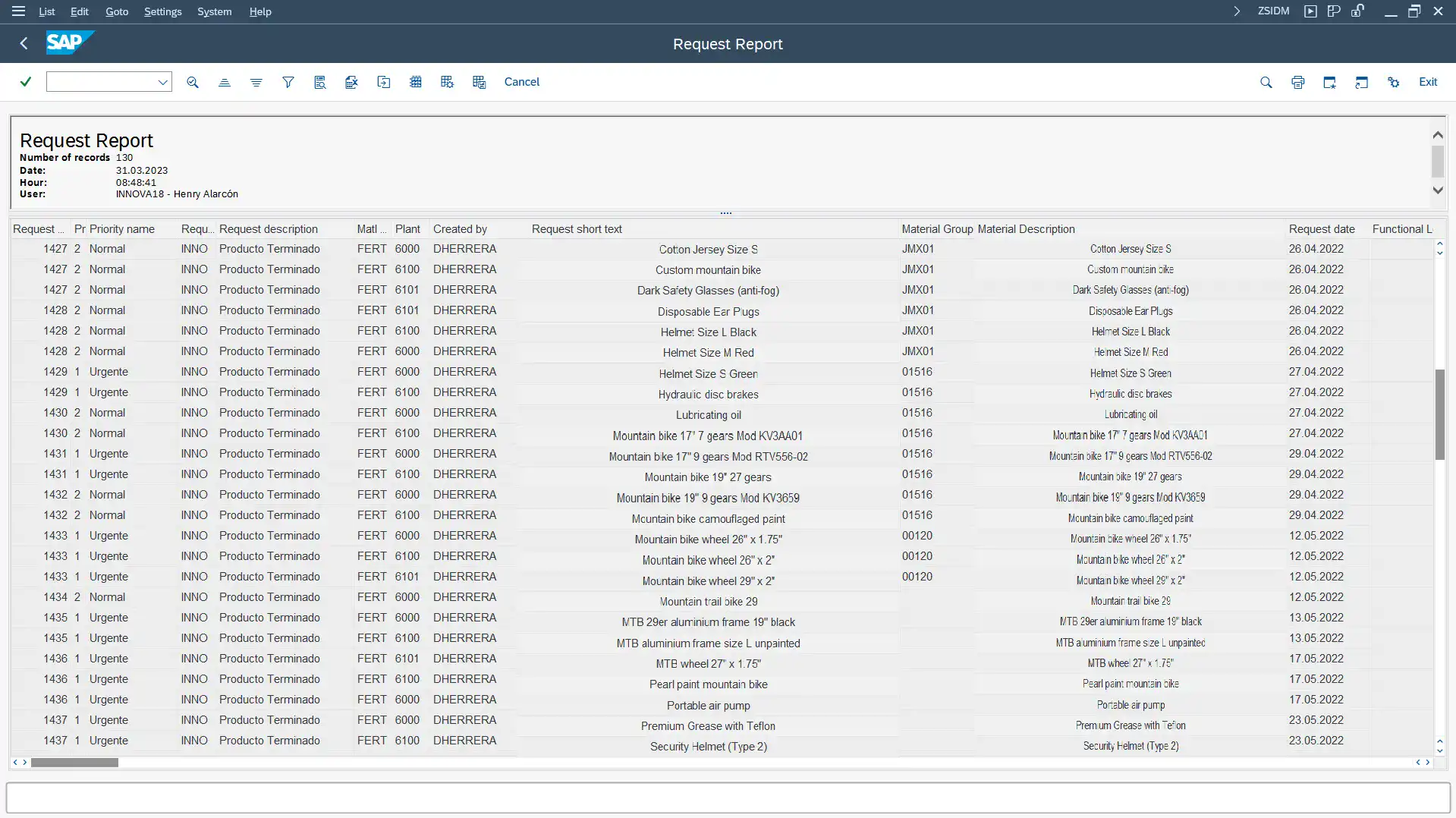

Material discharge requests

- Any user can "request" the creation of a material, directly in the App, without the need for emails or forms in other applications.

- You can configure which fields the applicant must fill in, depending on the business scenario.

- Then each responsible, according to the business rules, will be able to complete or approve information until finally creating the material in SAP, with all the required validations.

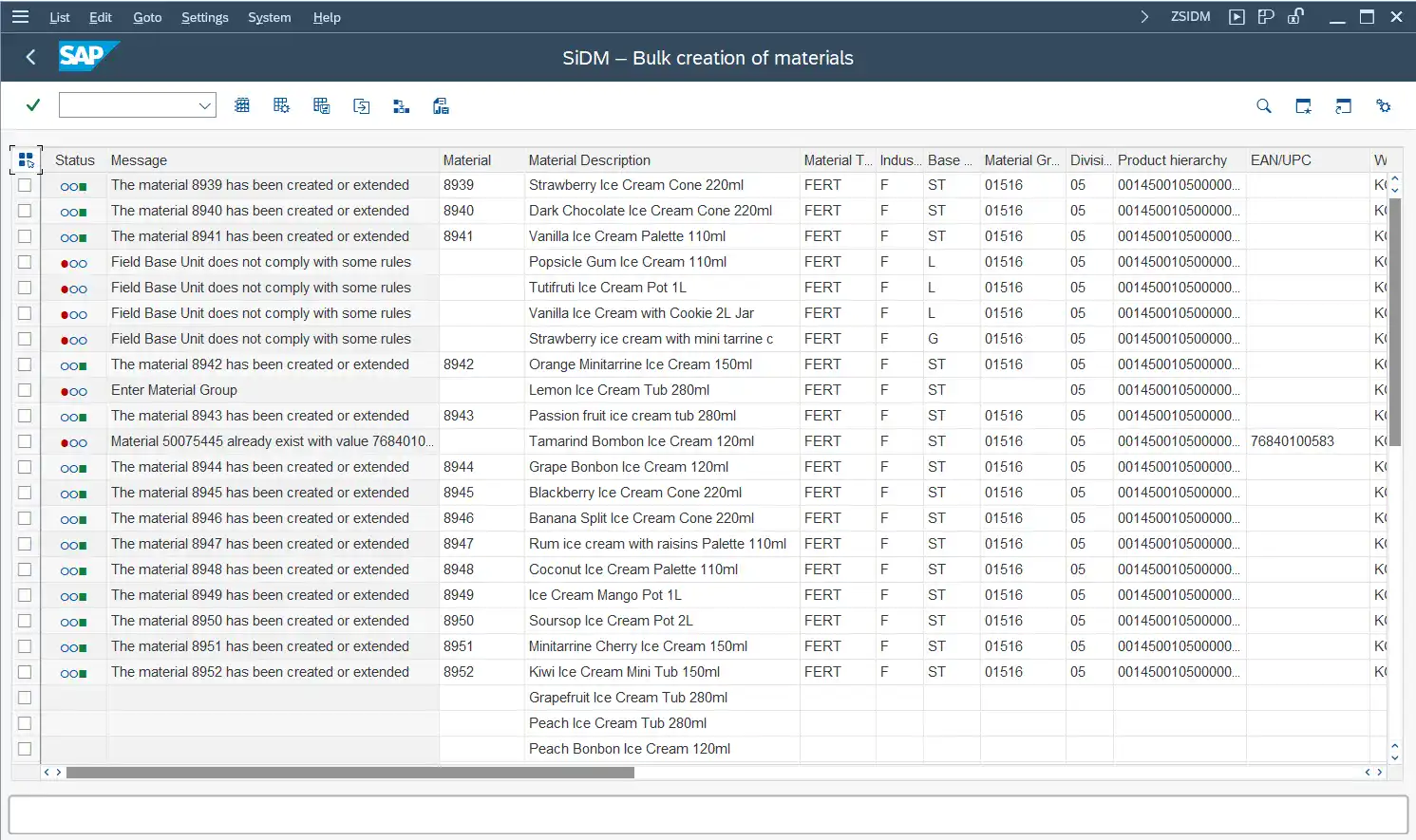

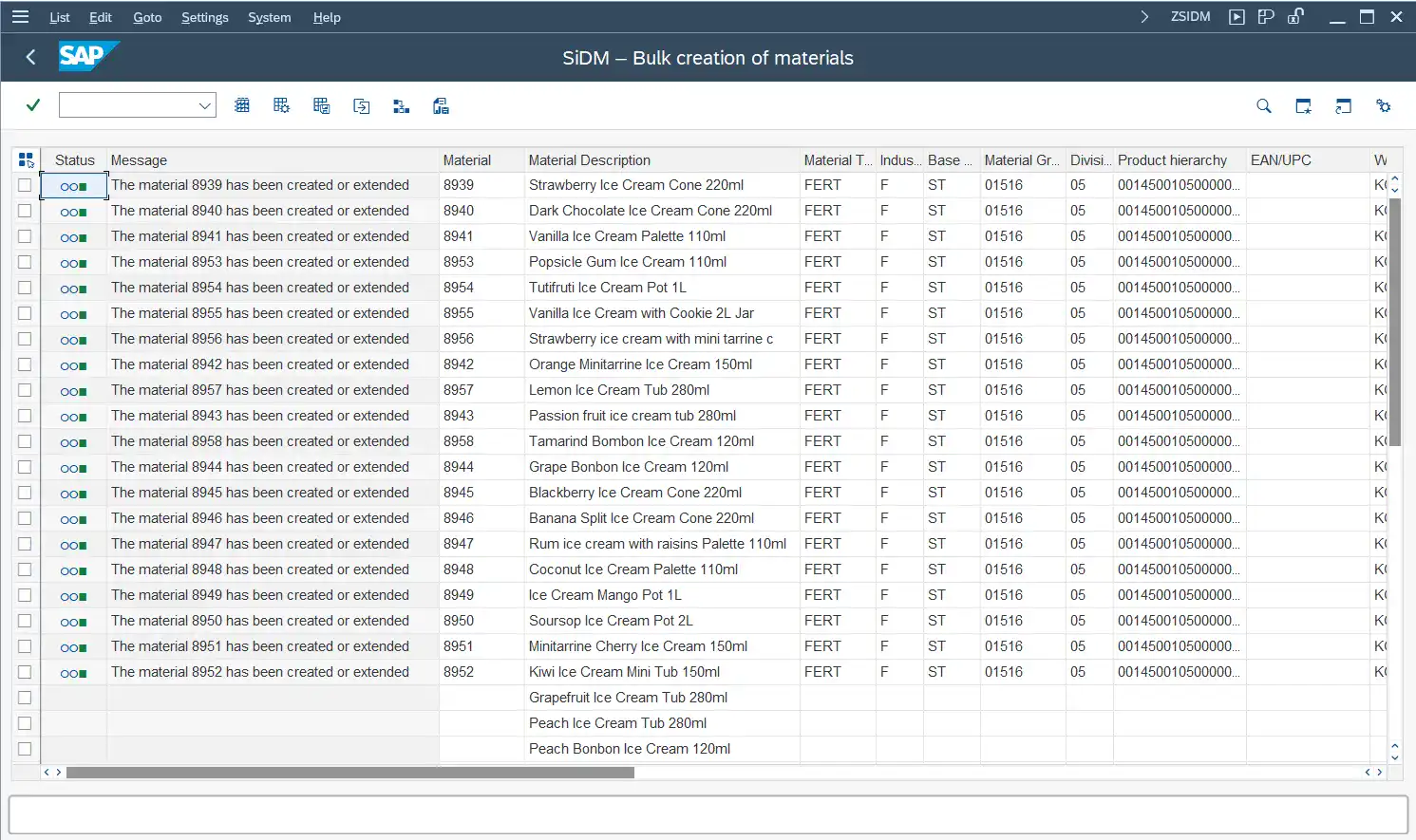

Direct and massive creation of materials

- It is possible to create multiple materials directly and massively, through an editable ALV, with standard validations (mandatory fields, only existing values) and second level validations (field value rules, avoid repeated materials through key fields). With options such as mass adoption of a model material or copying from Excel templates.

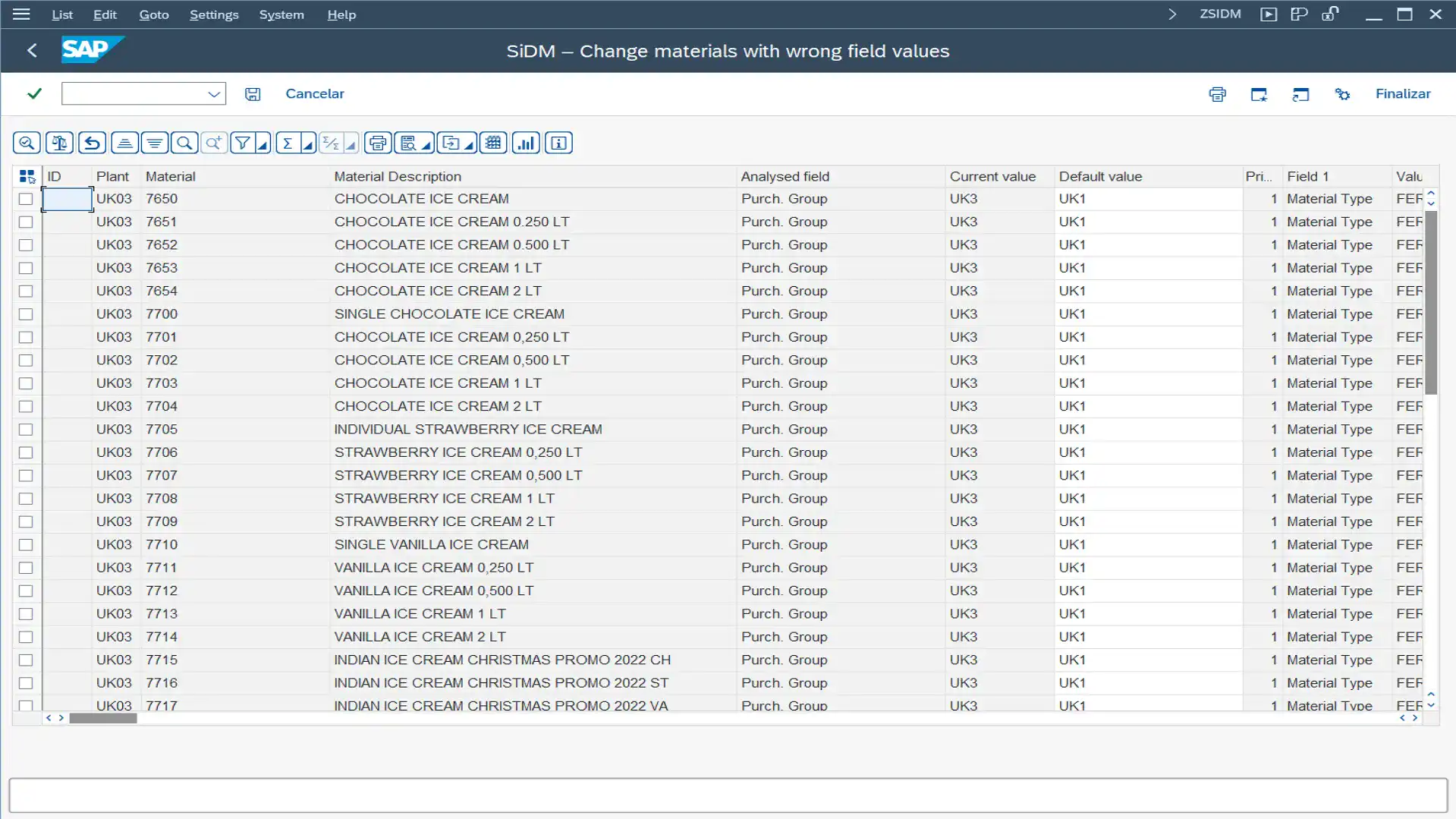

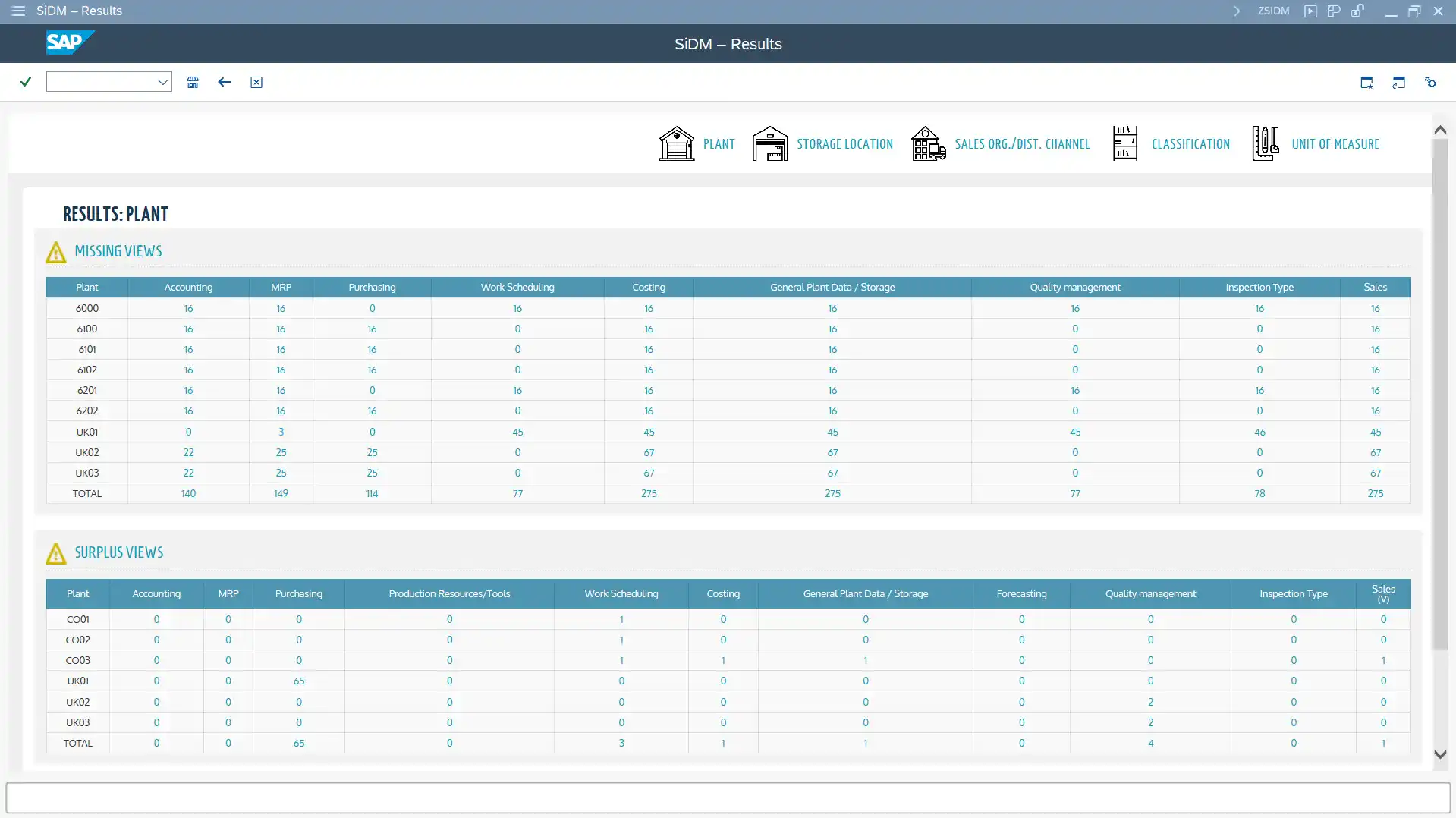

Correction of existing data (Data cleaning)

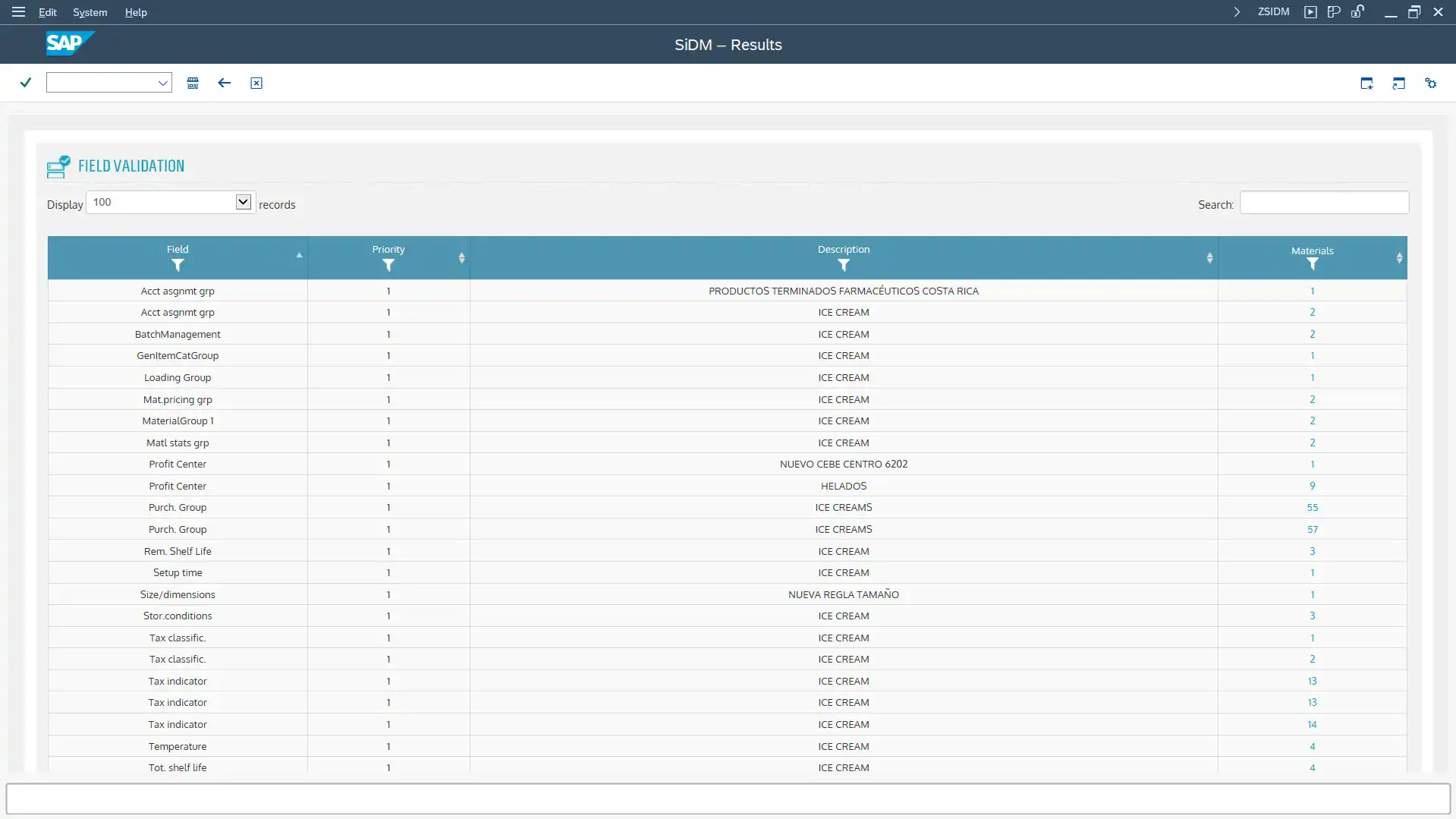

SiDM Materials has powerful debugging functions such as:

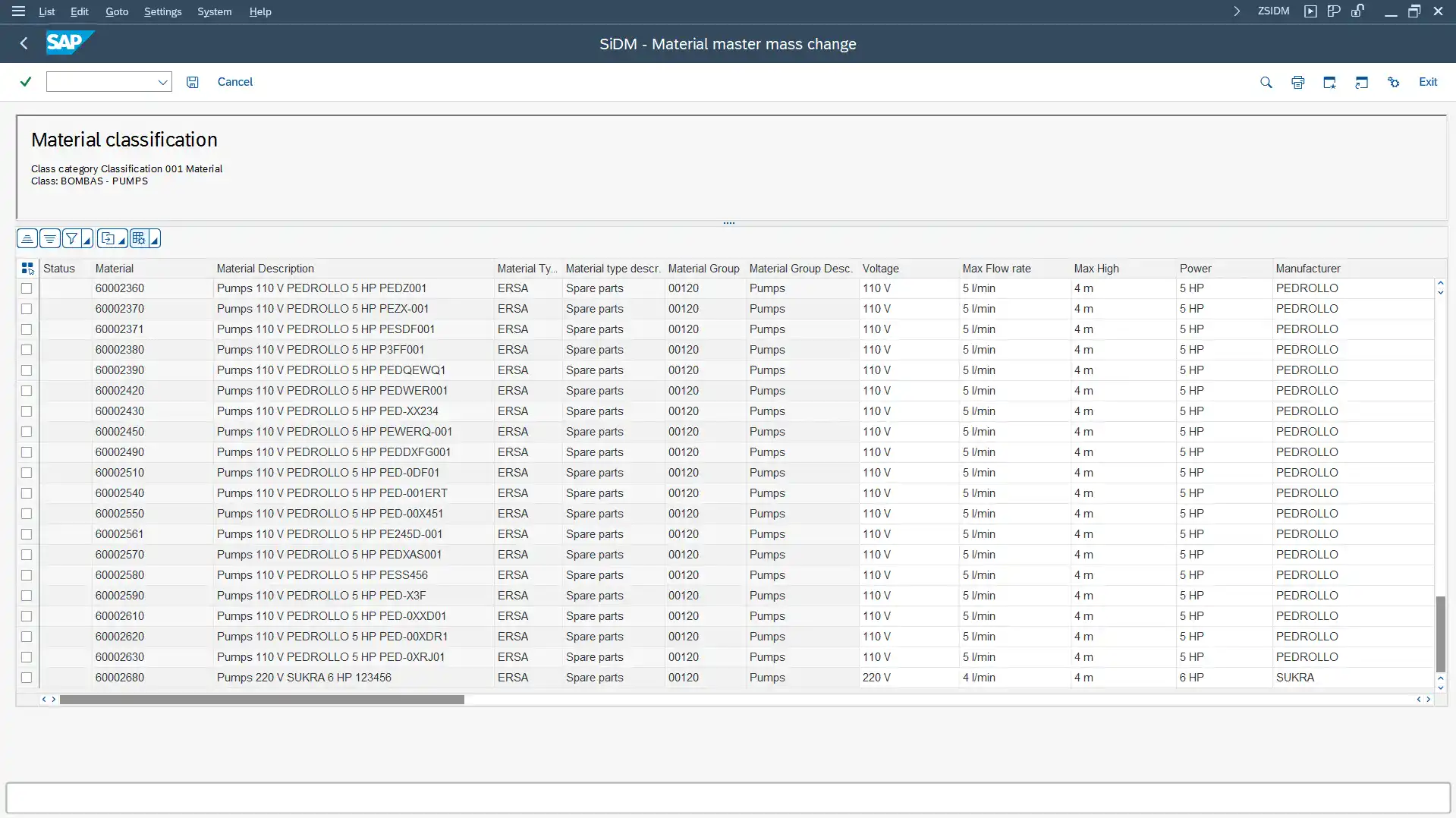

- Automatic correction of fields in existing materials by means of business rules.

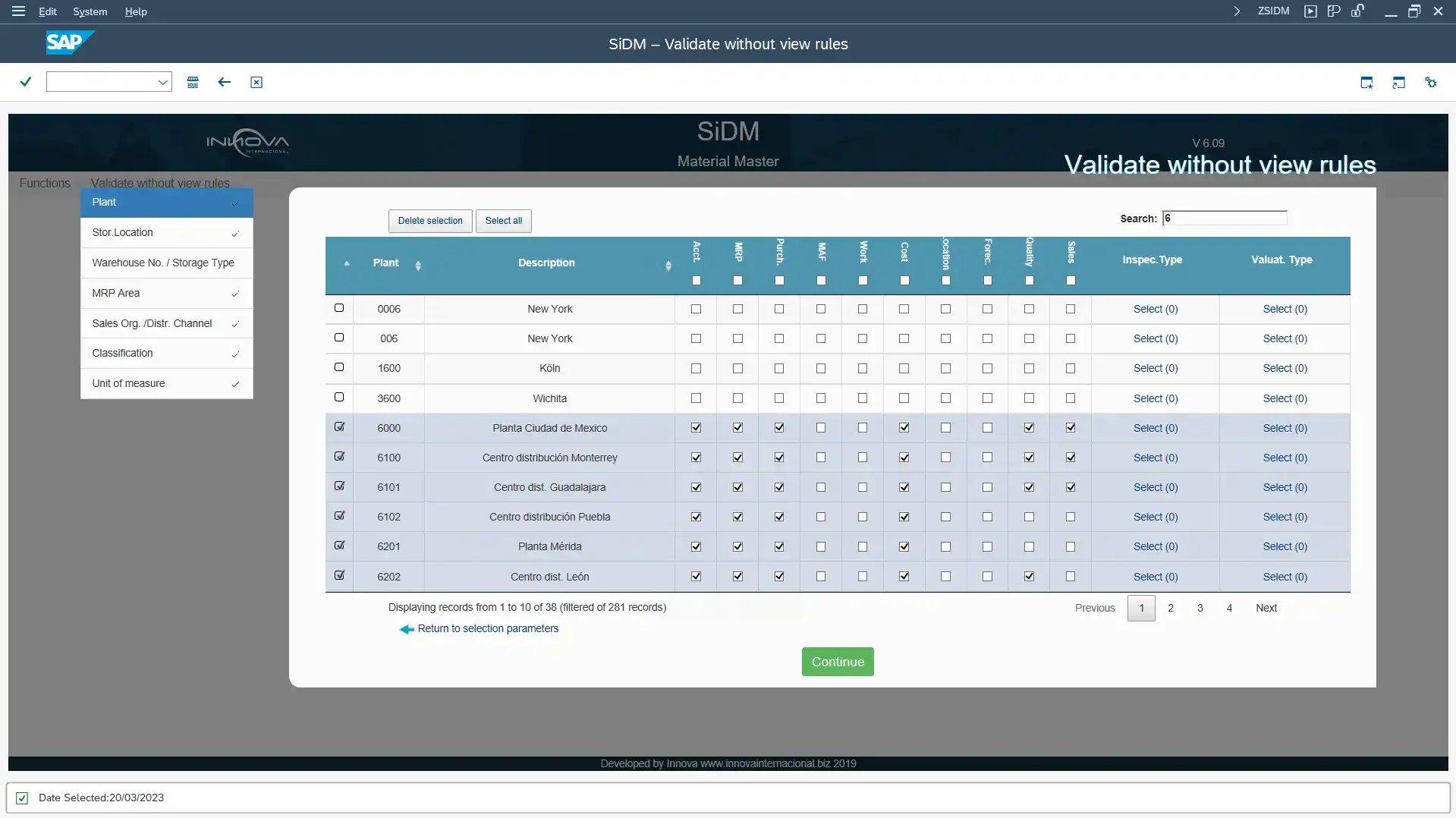

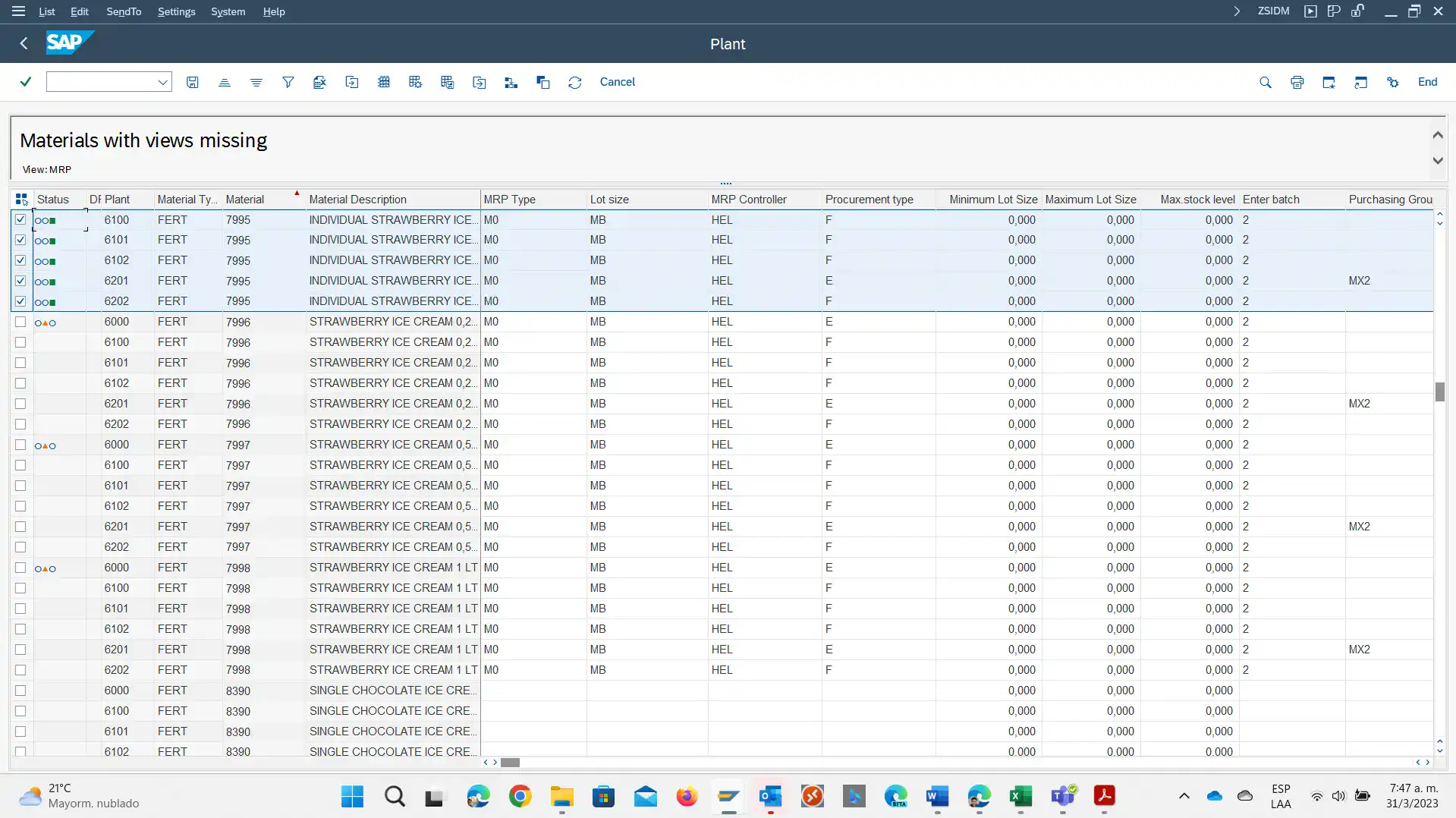

- Extension of incomplete materials or with missing views.

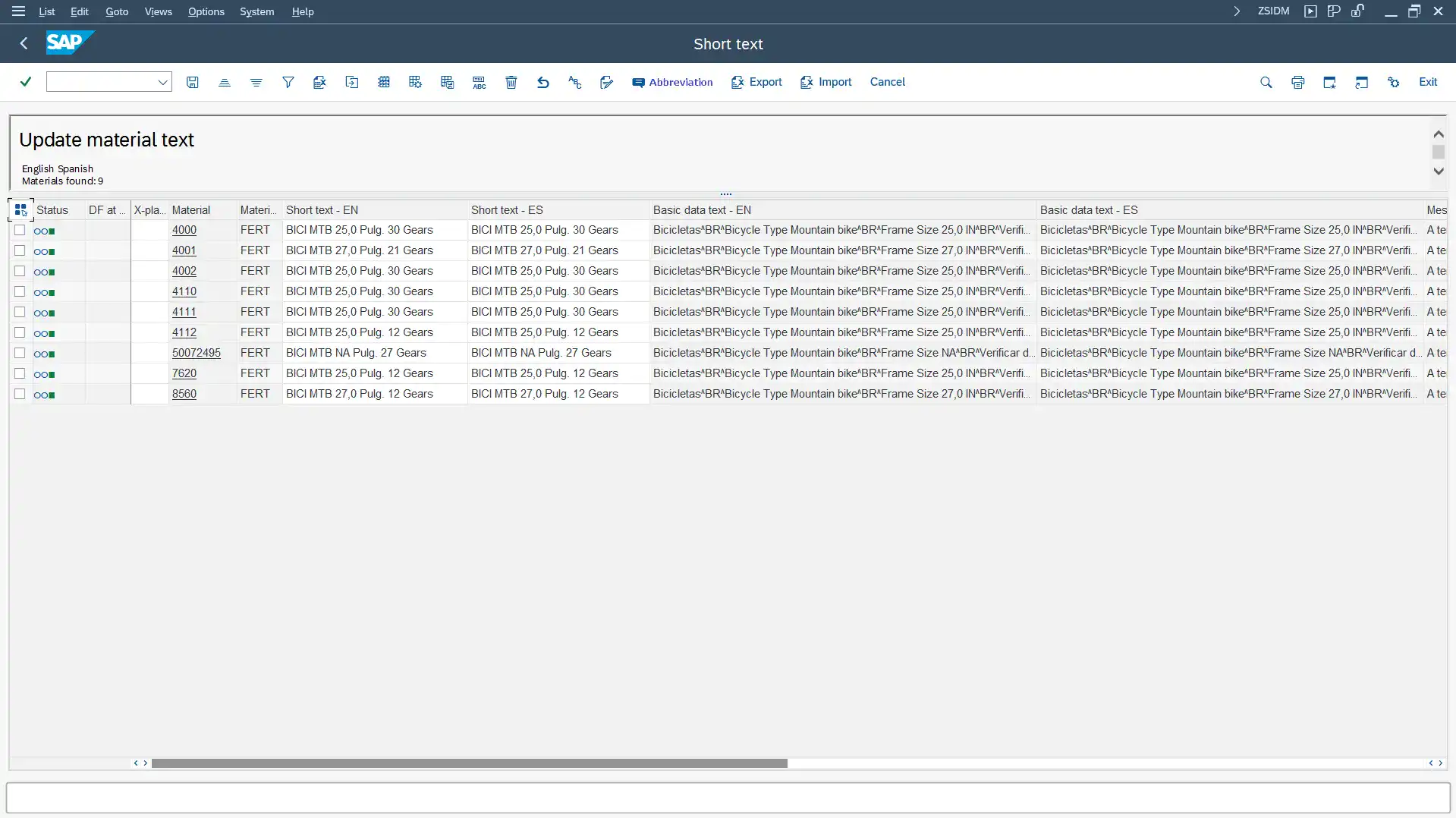

- Massive update of texts, manually or by means of business rules.

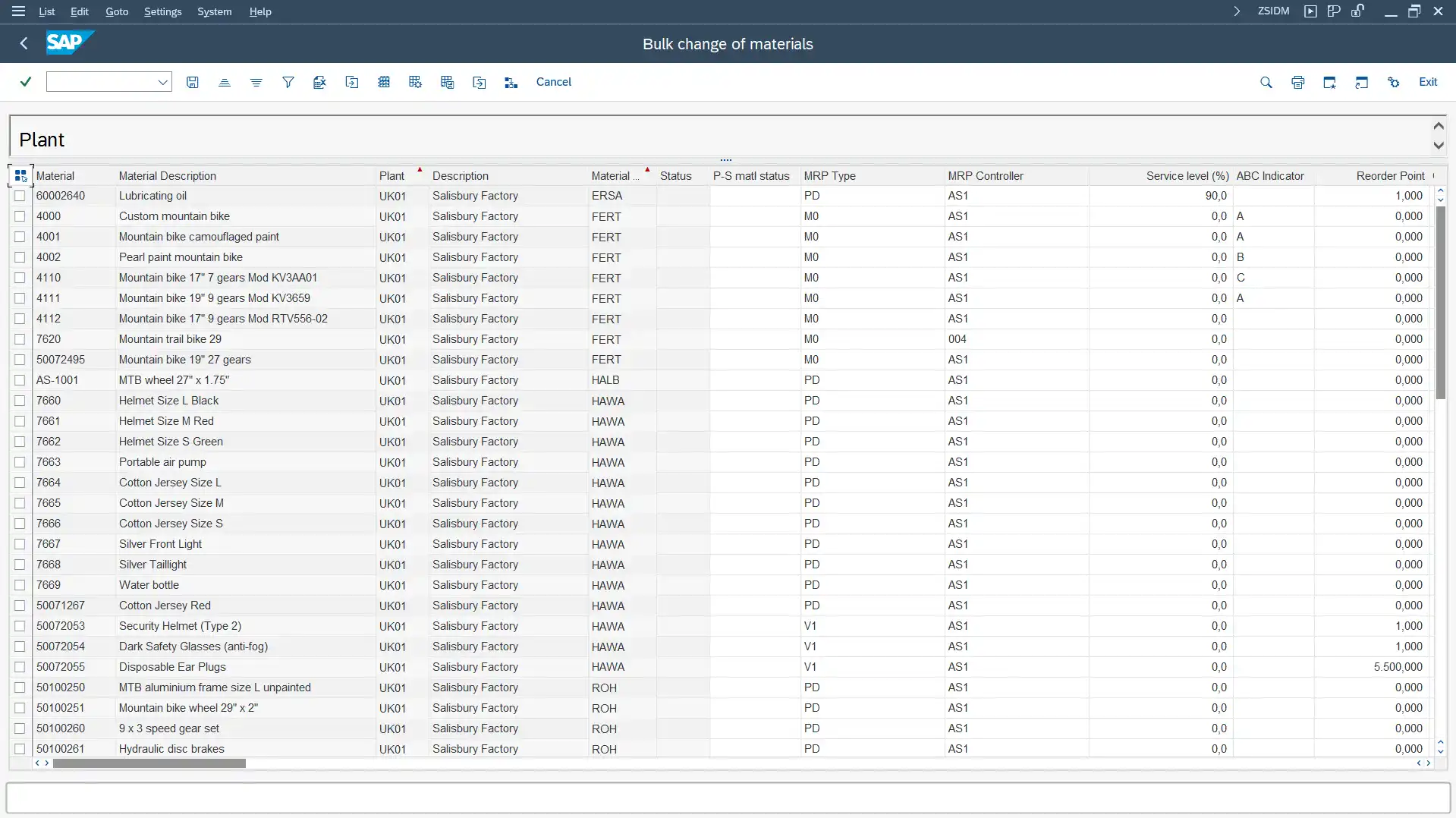

- Mass modification, by means of rules, from templates, model material or manually.

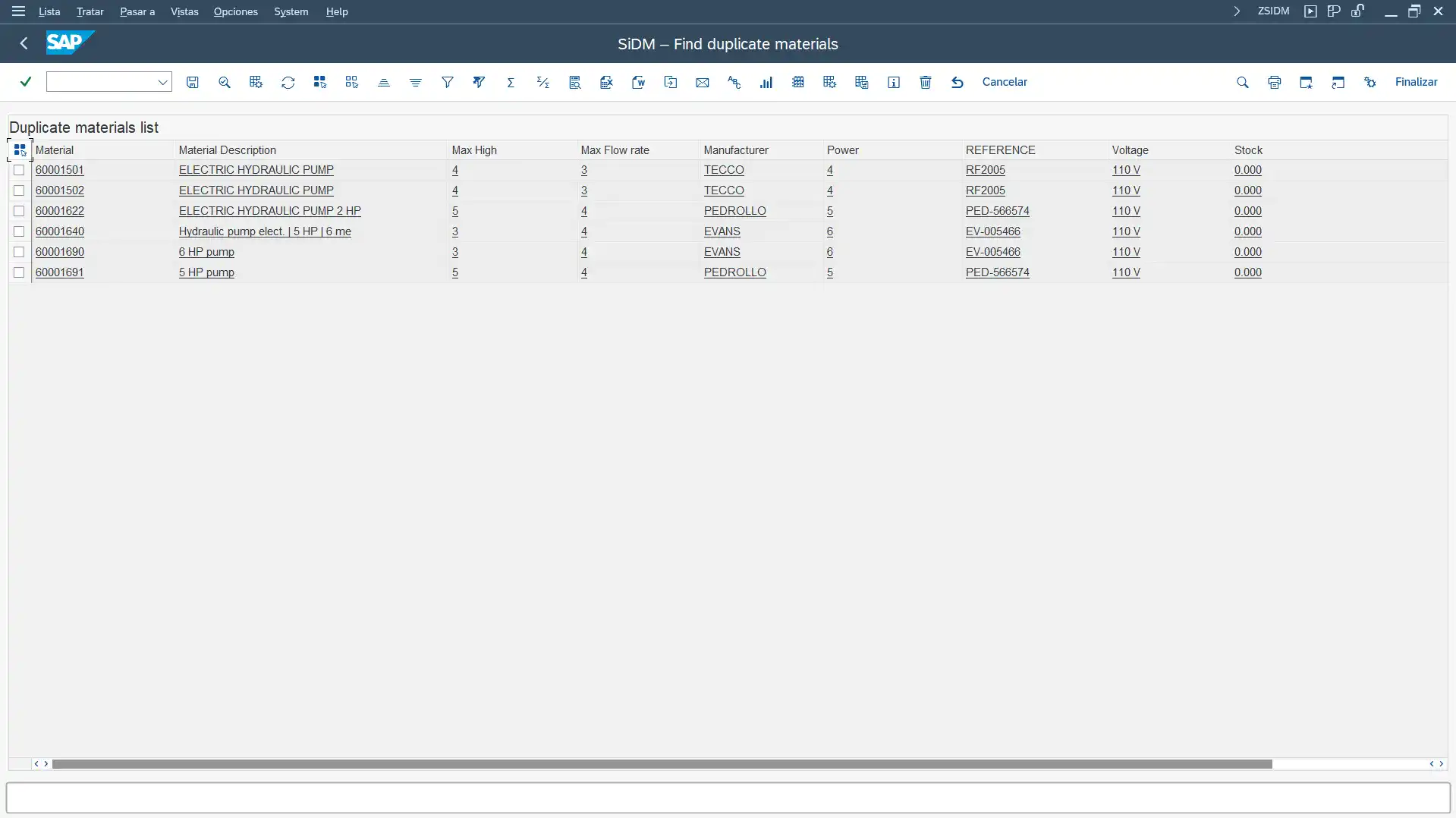

- Search for repeated materials based on text, classification characteristics or key fields.

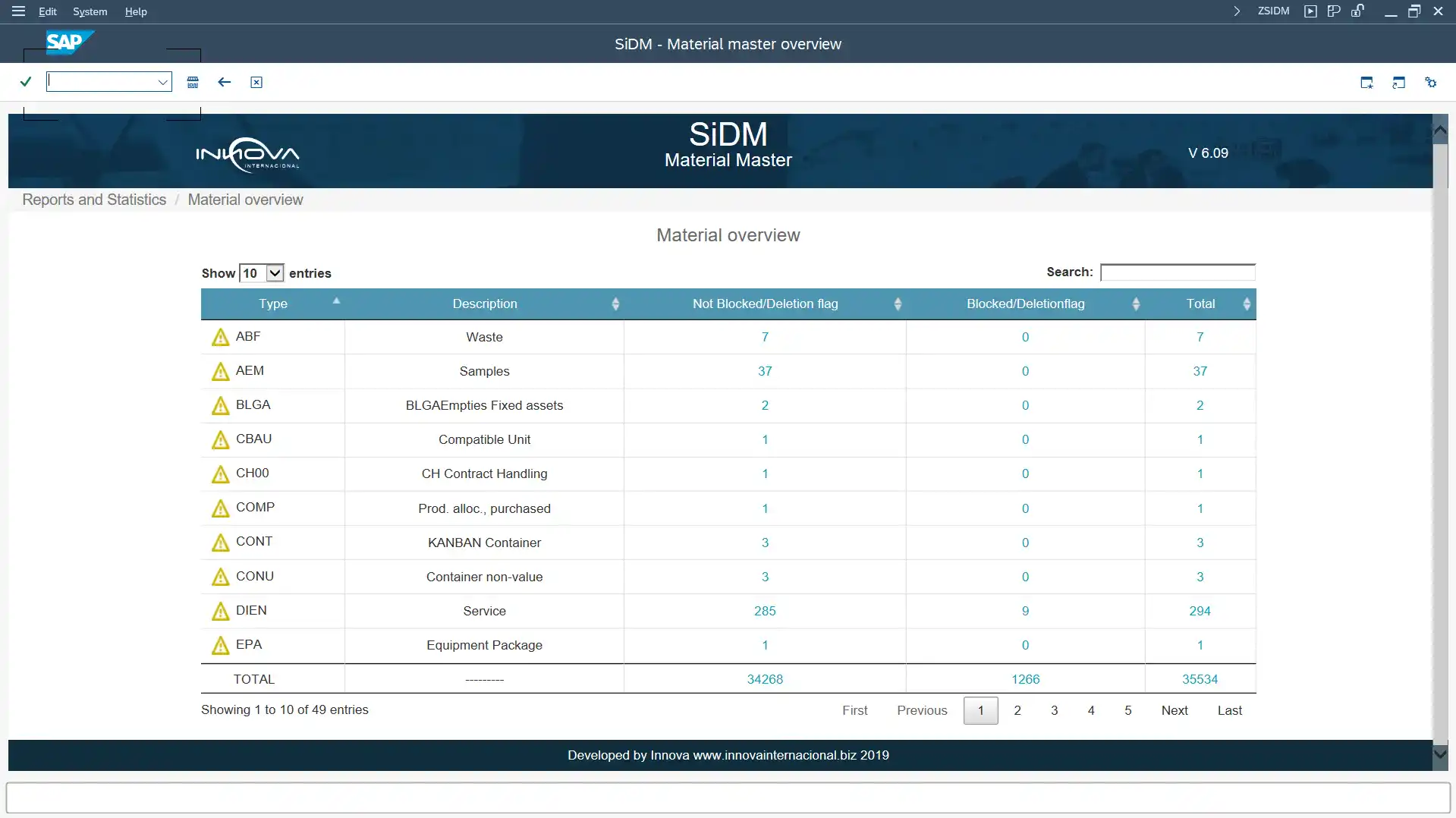

Reports

Intuitive and user-friendly for data analysis and maintenance, such as:

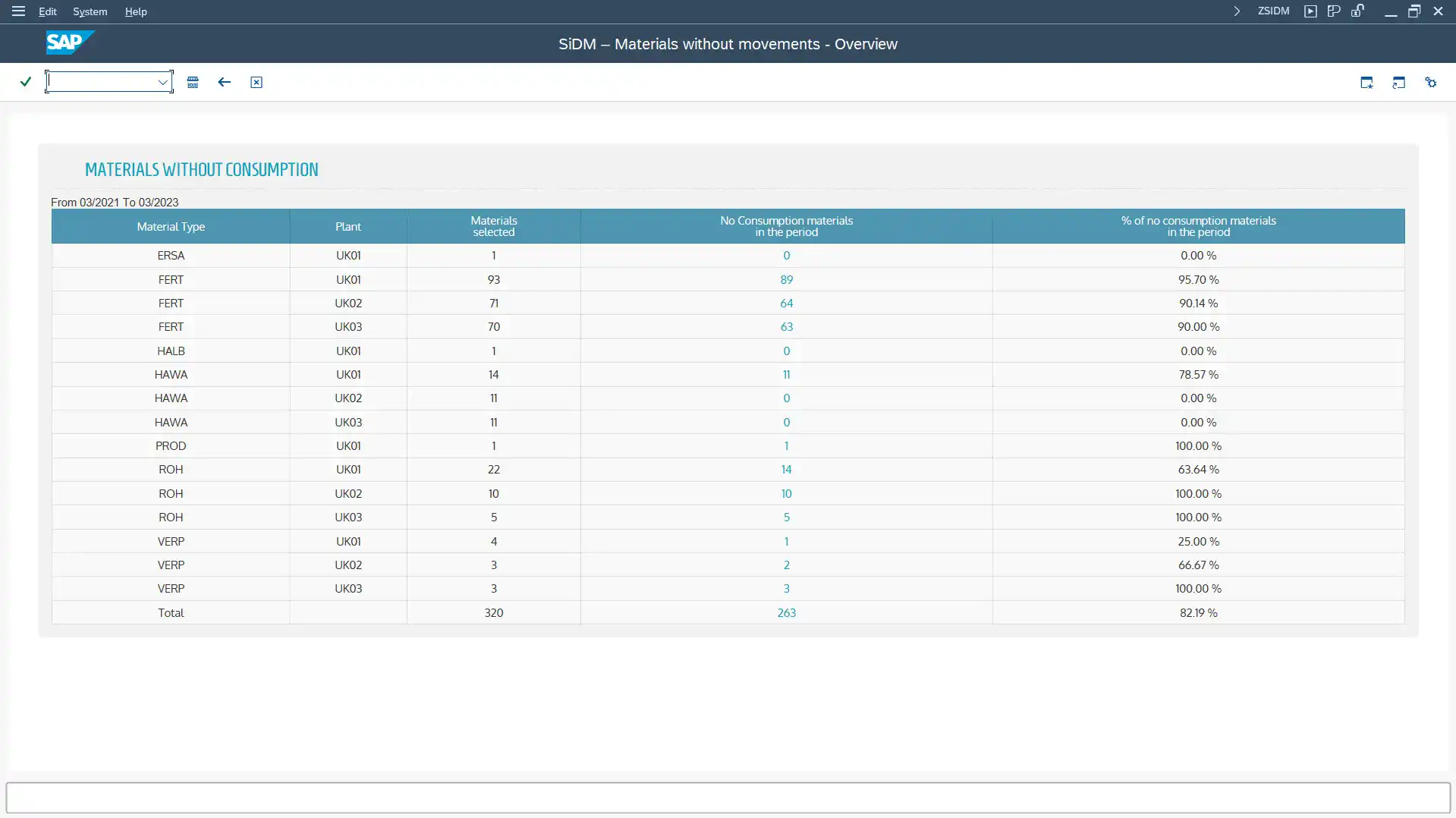

- Materials without consumption, to evaluate obsolete stock or mark for deletion.

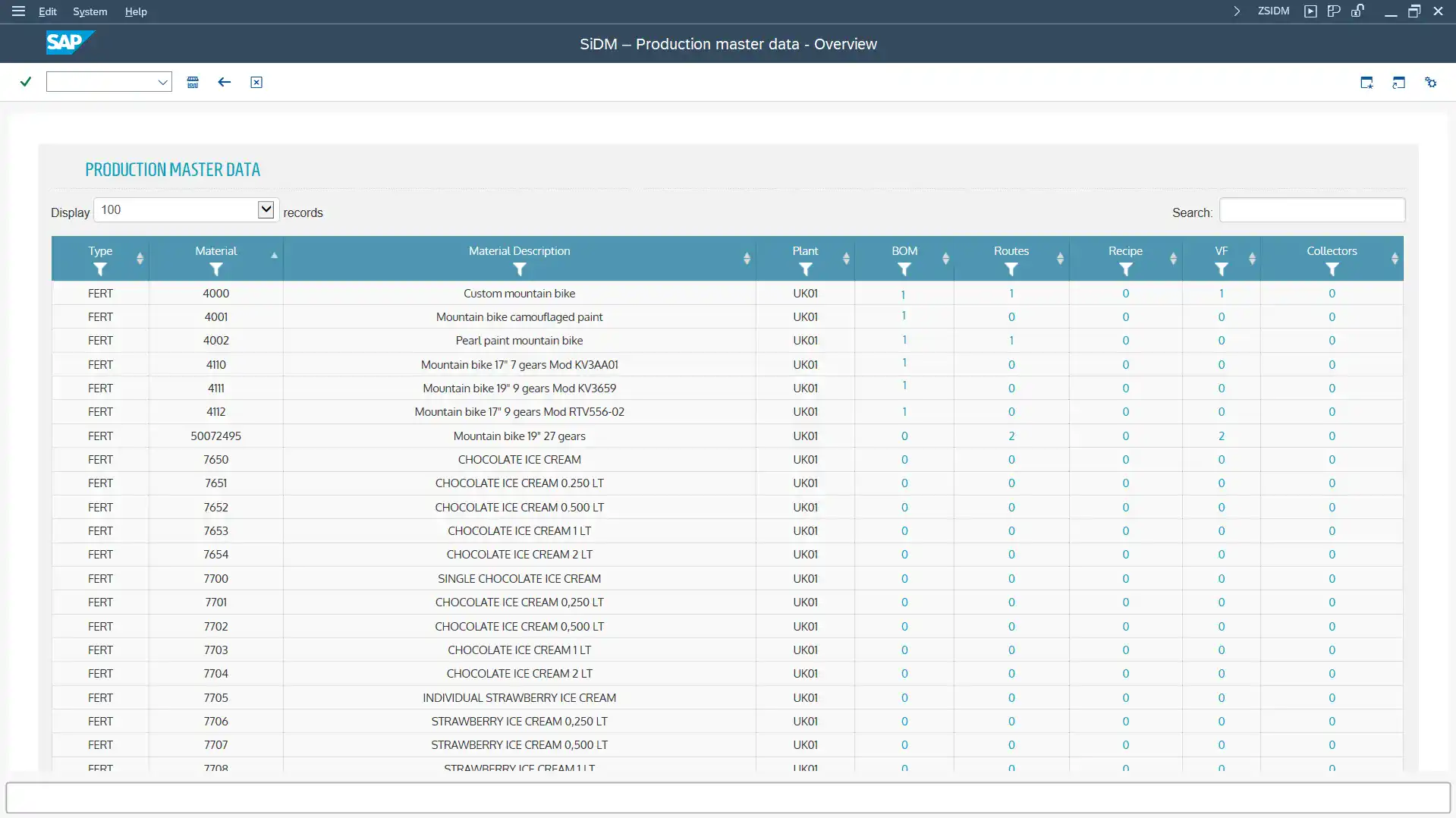

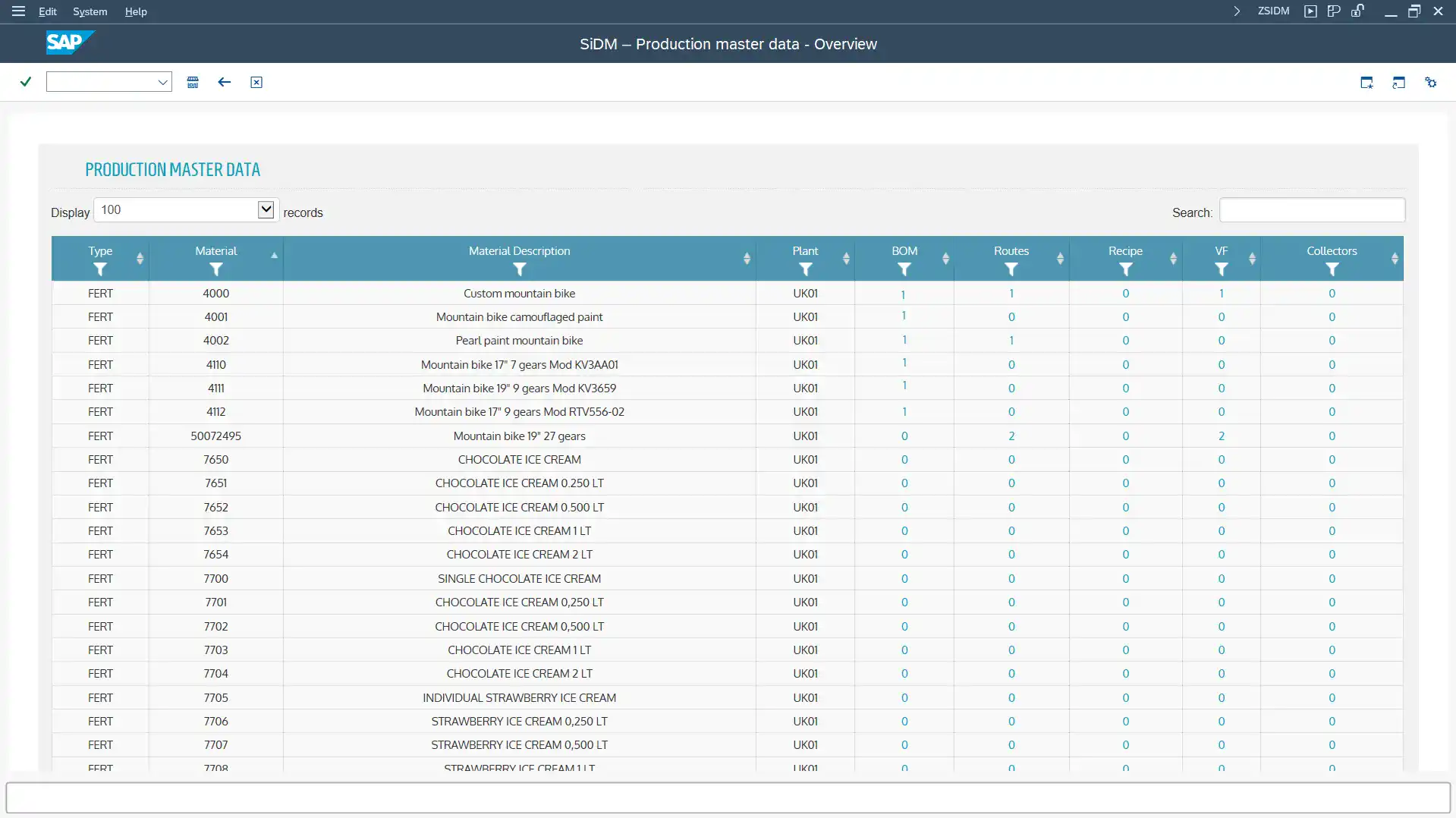

- Production data, evaluate in materials to be manufactured if they have lists, routings, production versions.

- Summary and detail of existing materials.

- As well as auditing the creation processes by means of applications.

Production data

- It is possible to configure in material registration requests, whether the creation of bills of material, routings or recipes and production versions is required to complete a request. In this way, it ensures the creation of all necessary data for a material being manufactured.

Benefits

Learn about the advantages of implementing our apps

For the IT department

Easy to implement

It only requires importing the installers and transporting them to each client, like any SAP change.Secure

With SAP standard authorization objects and some of the App’s own authorization objects, it ensures that control and segregation of duties is maintained through SAP standard user and role management.No maintenance or support

With the Warranty, Support and Upgrades service, Innova is responsible for maintaining compatibility with the latest versions of the system, as well as support and clarification of doubts with the end user.For the entire company

Better data, better processes

Master data impacts, and is therefore fundamental to any business process, and to the adoption of any technology. From buying or selling materials, analyzing financial information, or even adopting analytics or pattern training for artificial intelligence, requires quality data.Fewer hours of support and correction, lower costs

Materials with errors can cause rework and hours of support to fix the problem. With SiDM M you ensure the automatic and correct creation of materials, saving valuable hours of master data and support staff, as well as reducing outsourced support costs.Know how in the application

Forget about manuals or documents that nobody reads. The correct way to create materials is registered in the business rules, inside SAP, and to be adopted automatically.Duplicate materials, duplicate inventory

Save money and space in your warehouse by identifying and eliminating duplicate SKU’s in your inventory. Reduce the risk of unnecessary purchases and avoid taking up additional storage space by optimizing your inventory process now!

Schedule your Demo

Easy to discover

Easy, 30 – 45 min to show you our solutions, online, so you can see in detail how your processes will be optimized in SAP.

Architecture

The simplest and fastest to implement application. Only one ABAP component within SAP (ECC or S/4 Hana), one transaction in the SAP GUI

Requirements:

- SAP ECC version 6.0 or higher, up to the latest version of SAP S/4HANA.

- ABAP component (Installed via OT import)

Frequently Asked Questions

Encuentra las respuestas a tus preguntas más comunes aquí.

Yes, all types of materials, including non-standard materials.

Yes, you can display, edit and create business rules for non-standard fields, as long as they exist as Append to the standard material master tables in SAP.

No, with the purchase of the application, any SAP user, according to the assigned permissions can use the application.

Yes, you can define rules for creating and/or extending materials with the Quality Management (QM) view and the different inspection types required in each plant.

Yes, it is possible to define rules to ensure that materials are created or extended with the different valuations used in each business process (new, repaired, imported, national, etc.).

No, you can create all the necessary rules, depending on the business scenarios that exist.

Complete list of functions

- Configuration of View Rules.

- Field rule configuration

- Configuration of text rules

- Initial configuration

- Abbreviations Configuration

- Configuration Request types

- Configuration Strategies and release codes

- Configuration Product parameters

- Creation of materials

- Visible validation

- Automatic validation and correction

- Validation of views without rules

- Field validation

- Maintain material texts

- Search for repeated materials

- Massive modification

- Request for creation of materials

- Application management

- Report of materials with no consumption

- Production data report

- Material detail report

- Material summary report

- Material creation / modification summary report

- Requests analysis